Cast iron casting is made by melting and casting iron, carbon, and graphite as the main raw materials at high temperatures.

In mechanical production, in order to eliminate the internal stress caused by high temperature in castings, stabilize the structure and size of castings, and improve mechanical properties, castings need to be placed outdoors for more than 6 months. With the change of temperature difference in nature, the internal stress of castings can be eliminated, and then cutting processing can be carried out. The overall structure of castings will be more stable and resistant to deformation.

We have a warehouse of over 6000 square meters for storing finished equipment and a long-term inventory of over 300 units of equipment.

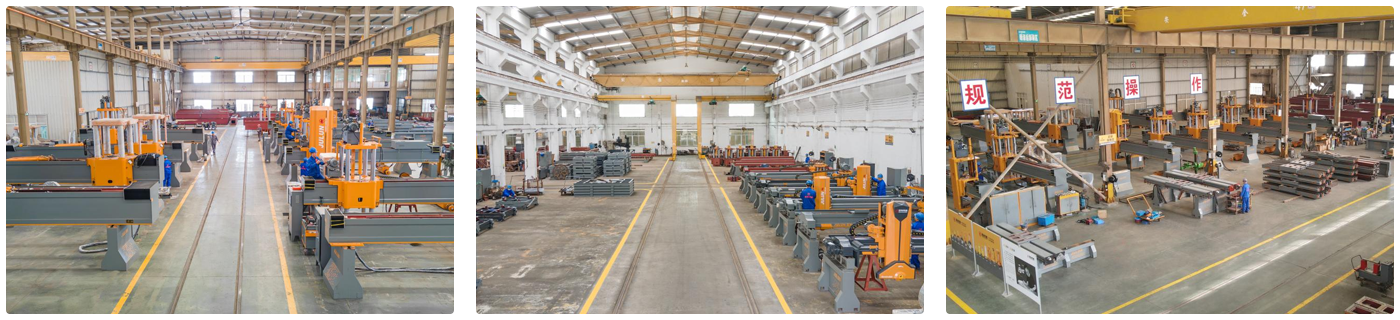

Product quality is the first vitality of the enterprise. Julun people always adhere to excellence, striving for every machine to achieve the highest quality. It is precisely the strict requirements for product technology that Julun constantly updates and upgrades its processing and manufacturing equipment. Currently, it is equipped with 66 advanced production and processing equipment and testing equipment at home and abroad, and its production and processing capacity has always been at the forefront of the industry.

The MAX block cutting machine, infrared bridge cutting machine, and automatic polishing machine independently developed and produced by Julun have always been highly praised by the market, and the MAX block cutting machine has been selected as the individual champion product of provincial manufacturing industry.

Julun people always serve every device with the purest craftsmanship spirit.